Moving Bed Biofilm Reactor (MBBR) Siltbuster ESI Enviropro

Analysis of Very-High Surface Area 3D-printed Media in a Moving Bed Biofilm Reactor for Wastewater Treatment. The study is about the wastewater treatment specific to ammonia/TAN using a high surface area 3D fabricate gyroid-shaped bio-carrier. Treatment performance was compared with the market available commercial bio-carrier.

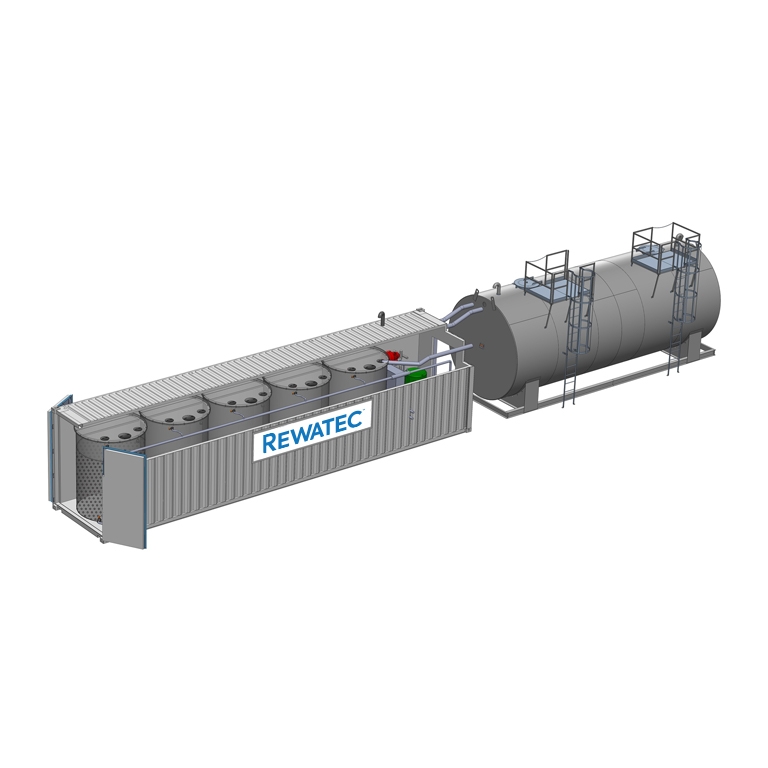

Moving bed biofilm reactors (MBBR) Rewatec

moving-bed-biofilm reactor (Ivanovic et al., 2006)] and. reactor (Artiga et al., 2005). Additionally, the coexistence of. shear force generated by circulating media on membranes

Moving Bed Biofilm Reactor Media at Rs 7000/cubic meter mbbr media in Sonipat ID 26193053691

ABSTRACT: The moving bed biofilm reactor (MBBR) can operate and in as roughing, a secondary, tertiary, and sidestream applications. 2- (anoxic) or 3-(aerobic) phase system with buoyant free-moving The plastic process includes a submerged biofilm reactor and liquid bioftlm carriers. These systems can be used for municipal and solids.

4 Schematic of a moving bed biofilm reactor (MBBR) Download Scientific Diagram

Moving Bed Biofilm Reactor (MBBR) systems, originally invented by the Norwegian University of Science and Technology in 1989, consist of an aerated treatment tank (similar to a activated sludge tank) with special plastic media or carriers that provide a surface promoting biofilm growth.The media are made of a material with a density close to the density of water (1 g/cm3).

Moving Bed Biofilm Reactor (MBBR Media)BIOETP

MBBR (Moving Bed Biofilm Reactor) media is an innovative technology employed in wastewater treatment processes. It consists of small, specially designed polyethylene biofilm carriers that provide a high surface area for beneficial microorganisms to grow. The MBBR media's unique design maximizes the biofilm surface area, enabling efficient.

PPT Moving Bed Biofilm Reactor MBBR for Nitrification/Denitrification PowerPoint Presentation

MBBR which is commonly known as moving bed biofilm reactor is a modern water treatment technology and process. It was first invented in the late 1980s by Professor Hallvard of the Norwegian University of science and technology.. MBBR is a highly effective biological water treatment process that is based on a combination of biofilm media and.

BIODOS Moving Bed Biofilm Reactor

Moving bed biofilm reactors (MBBRs) rely on the growth of biofilms on "carriers" in aeration tanks for wastewater treatment.. Media: Reactor is full of small plastic chips, also known as media or carriers, which provide surface area for biofilm to grow on them. Media have equal density as water, allowing them to mix throughout the fluid.

China Moving Bed Biofilm Reactor Bio Filter Media Manufacturers, Factory Customized Moving Bed

Given the necessity of advanced biological treatment processes, moving bed biofilm reactor (MBBR) is preferred for treating high organic and nutrient load and recalcitrant contaminants with enhanced removal efficiency, less footprint, reduced operational difficulties, and increased technical feasibility for large-scale as well as package-based.

Moving Bed Biofilm Reactor (MBBR Media)BIOETP

Moving bed biofilm reactor. Moving bed biofilm reactor (MBBR) is an advanced wastewater treatment technology, which employs the benefits of both biofilm and activated sludge processes for highly efficient wastewater treatment [ 14 ]. Developed in the 1980s, MBBR has been established in the last two decades worldwide as a simple, robust.

Moving Bed Biofilm Reactor (MBBR) Ideal MBBR™ YouTube

In moving bed biofilm reactors (MBBR) biomass grows as biofilm on plastic carriers that move freely into wastewater; tanks are similar to activated sludge reactors, and they have screens or sieves to avoid carriers' loss; aerated reactors are mixed by aeration itself, while anoxic and anaerobic reactors are mixed mechanically..

Moving Bed Biofilter Reactors (MBBR) for Aquaculture

The dominance of comammox Nitrospira over canonical ammonia oxidizers in a moving bed biofilm reactor (MBBR) fed with synthetic mainstream wastewater is reported and features suggest a low apparent oxygen affinity for the comamm ox Nitro Spira-dominated biofilms in the high-DO nitrifying MBBR. Expand

China Strong K1 K3 K5 Moving Bed Biofilm Reactor MBBR Media Manufacturer and Supplier TopJoy

Moving Bed Biofilm Reactors (MBBRs) can efficiently treat wastewater by incorporating suspended biocarriers that provide attachment surfaces for active microorganisms. The performance of MBBRs for wastewater treatment is, among other factors, contingent upon the characteristics of the surface area of the biocarriers. Thus, novel biocarrier topology designs can potentially increase MBBR.

Moving Bed Biofilter Reactors (MBBR) for Aquaculture

Effects of media length on biolms and nitrication in moving bed biolm reactors Kody A. Garcia , Patrick McLee 1, Andrew J. Schuler * Department of Civil, Construction, and Environmental Engineering, MSC01 1070, University of New Mexico, Albuquerque, NM, 87106, USA. Effects of media length on biofilms and nitrification in moving bed biofilm.

The Ultimate Guide to MBBR (Moving Bed Biofilm Reactor) Gustawater

1. An overview of MBBR development. Biofilm reactors mostly used for the removal of organic matter and nutrients (i.e., nitrogen and phosphorus), prior the development of moving bed biofilm reactors occurred, were biological trickling filters, aerated submerged fixed film biofilm reactors, fluidized-bed reactors, and rotating biological contactors (Rittmann, 1982).

Moving Bed Biofilm Reactor Capacity 50 KLDEnvmart

The moving bed biofilm reactor (MBBR) can operate as a 2- (anoxic) or 3-(aerobic) phase system with buoyant free-moving plastic biofilm carriers. These systems can be used for municipal and industrial wastewater treatment, aquaculture, potable water denitrification, and, in roughing, secondary, tertiary, and sidestream applications..

Moving Bed Biofilm Reactor Anoxic & Aerobic MBBR Mixing

The moving bed biofilm reactor (MBBR) can operate as a 2- (anoxic) or 3- (aerobic) phase system with buoyant free-moving plastic biofilm carriers. These systems can be used for municipal and.